Introduction to Offset Printing

Offset printing is a widely used technique in the printing industry. Its significance lies in its ability to produce high-quality prints efficiently. This article delves into the world of offset printing, explaining how it works, its history, and its applications.

How Offset Printing Works

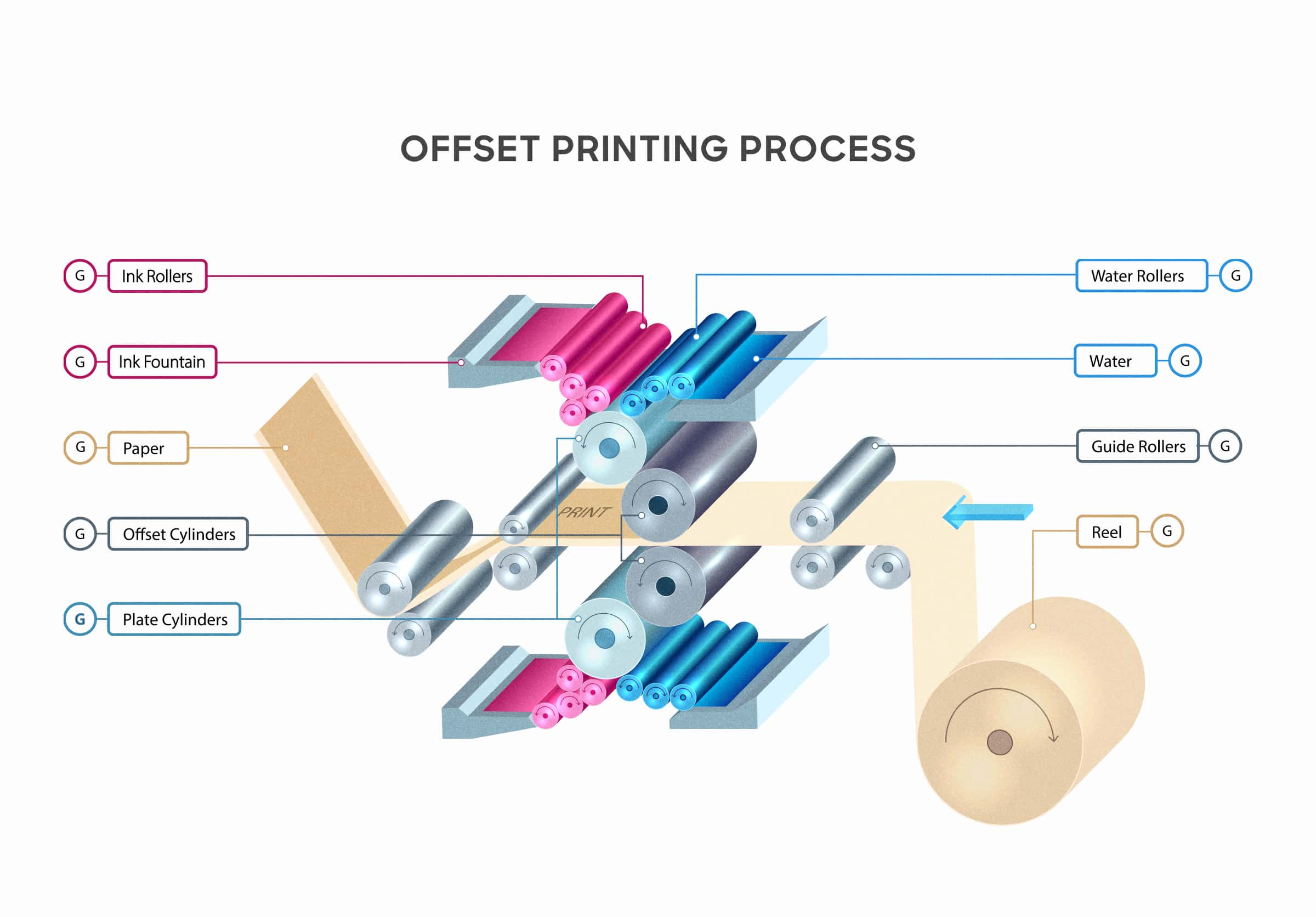

Offset printing, also known as offset lithography, is a sophisticated printing method that involves a series of intricate processes. It all begins with a simple concept: oil and water don’t mix. Here’s how it works:

- Image Transfer: The process starts with creating a printing plate. This plate contains the image or text to be printed. In offset printing, this image is typically etched or burned onto the plate. This printing plate is usually made of aluminum, and the image area is hydrophobic (water-repellent), while the non-image area is hydrophilic (water-attracting).

- Ink Rollers: The printing plate is dampened with water and ink. Ink rollers apply ink to the image area, while the non-image area repels ink due to its water-attracting properties.

- Image Transfer to Blanket Cylinder: The image is then transferred from the plate to a rubber blanket cylinder. The rubber surface of the blanket cylinder is essential for its ability to conform to the paper’s surface, ensuring a clean and consistent transfer of the inked image.

- Final Transfer to Paper: The image is finally transferred from the blanket cylinder onto the paper or another printing surface. The result is a clean, sharp image on the paper.

History of Offset Printing

Offset printing has a rich history dating back to the late 19th century. It evolved from earlier printing techniques, such as letterpress and stone lithography. Notable pioneers in offset lithography, including Ira Washington Rubel and Frank Prout, played pivotal roles in advancing the technology.

Offset Printing Press

Offset printing presses come in various types and configurations, with each designed for specific applications. Sheet-fed offset presses are commonly used for smaller print runs, while web offset presses are more suitable for high-volume, continuous printing. Offset printing presses offer advantages like high-quality output, speed, and cost-effectiveness.

Offset Print vs. Other Printing Methods

Offset printing is just one of several printing methods available today. To determine if it’s the right choice for your printing needs, it’s essential to understand how it compares to other techniques like digital printing and flexography.

Offset Printing Materials

Choosing the right materials for offset printing is crucial. The type of paper, ink, and printing plates used can significantly impact the final result. Offset printing is known for its ability to work with a wide range of paper types, including glossy and matte finishes.

Prepress Process in Offset Printing

Before the actual printing begins, there are several critical prepress steps. This includes designing and laying out the content, preparing the files for printing, and creating the printing plates. Proper prepress preparation ensures that the final output is of the highest quality.

Offset Printing Technology Advancements

Offset printing technology has seen substantial advancements over the years. Modern offset presses incorporate cutting-edge features that improve efficiency and reduce environmental impact. Additionally, there is a growing emphasis on sustainability and reducing the environmental footprint of offset printing.

Common Applications of Offset Printing

Offset printing excels in various applications. It is commonly used for printing books, brochures, magazines, and packaging materials. It’s also employed in the production of marketing materials, stationery, and promotional items. Real-world examples of offset printing are all around us.

Offset Printing Benefits and Limitations

Understanding the advantages and limitations of offset printing is essential when deciding whether to use this technique. The benefits include high-quality output, cost-effectiveness for large print runs, and the ability to work with various paper types. However, offset printing can be less economical for small quantities and requires a longer setup time.

The Future of Offset Printing

The world of offset printing is not stagnant. It continues to evolve as technology advances. Trends in the offset printing industry include automation, improved energy efficiency, and reduced waste generation. The industry is committed to embracing sustainable practices and reducing its impact on the environment.

Conclusion

Offset printing remains a crucial player in the world of printing. Its ability to deliver high-quality, cost-effective prints ensures its enduring significance in the industry. Whether you’re printing a best-selling novel, a glossy magazine, or a beautiful brochure, offset printing is likely behind the scenes, making it all happen.